Our Technical Hub is here to support your architectural queries and product questions. As manufacturers of our systems, we know the complexities of creating beautiful and functional designs.

Explore and download our specification guides, acoustic information and technical data sheets. These guides along with our FAQ’s are the best tools to support your learning and understanding of the systems we produce, and how easy it is to specify and install.

Why Choose Supaslat?

Our SupaSlat range of modular fr-rated timber-style slatted systems provides a winning combination of natural appeal with a full range of finishing options.

SupaSlat ensures rapid installation, including full and easy access to services and acoustic performance.

Is SupaSlat fire rated?

Yes! SupaSlat panels are tested and certified to Euroclass B as fully assembled systems, providing reliable fire compliance as a complete product.

How do I know which SupaSlat option is right for me?

There’s a SupaSlat option for every project!

Consider:

WHAT ARE THE FINISH OPTIONS?

Vtec’s comprehensive finishing solutions provide you with a fantastic spectrum of colours and effects. Our factory-applied finishes give so much more than “just another covering” and leave you with creative ideas to choose from, to design something truly different for your clients.

SUPALAMI: Applied to the face of the slats with matching edging, this laminate provides you with a great-looking finish without the cost of solid timber veneer. Available in a variety of finishes.

CAN SUPASLAT WORK WITH LIGHTING AND OTHER ELEMENTS?

Yes, SupaSlat is very flexible and we can work with you to incorporate specific requirements such as lighting, heating & ventilation, fire detectors & sprinklers and CCTV requirements. We’ve worked on many complex projects and seen a wide range of other elements being used in conjunction with our SupaSlat systems to great effect.

Please talk to us if you envisage a particular design challenge and require a more bespoke approach.

CAN SUPASLAT INCORPORATE ACCESS REQUIREMENTS?

Yes, SupaSlat is very flexible and we can work with you to incorporate specific access requirements in both walls and ceiling, such as doorways and access hatches.

We’ve collaborated on a range of projects with particular access challenges and incorporated bespoke solutions into the specification.

WHAT SIZES ARE THE SLATS?

Vtec standard SupaSlat sizes are:

SupaSlat 1-25 – 50mm width, 19mm height, 25mm gap, 75mm centres

SupaSlat 1-50 – 50mm width, 19mm height, 50mm gap, 100mm centres

SupaSlat 2-30 – 70mm width, 19mm height, 30mm gap, 100mm centres

SupaSlat 2-80 – 70mm width, 19mm height, 80mm gap, 150mm centres

SupaSlat 4-31 – 19mm width, 50mm height, 31mm gap, 50mm centres

SupaSlat 4-56 – 19mm width, 50mm height, 56mm gap, 75mm centres

SupaSlat 5-56 – 19mm width, 70mm height, 56mm gap, 75mm centres

SupaSlat 5-81 – 19mm width, 70mm height, 81mm gap, 100mm centres

WHAT THICKNESS ARE SUPASLAT PANELS?

Slat thickness varies subject to the installation method and possibly the service integrations.

Please contact our Technical Department for advice.

Please refer to the previous question for standard sizes.

HOW MANY SUPASLAT PANELS DO I NEED?

Please provide us with the dimensions of the area you wish to cover and our Technical Department can produce a panel layout scheme to quantify this, and also to assist your installers on site.

Why is SupaSlat supplied as a panel and not loose components?

SupaSlat is supplied as a complete panel system to ensure factory-level quality, fire compliance, and rapid installation. By manufacturing the panels off-site to your project’s exact dimensions, there’s no need for on-site cutting, eliminating mess, waste, and risk to the fire-rated finishes. It also means consistent appearance, acoustic performance, and Euroclass B fire certification across the entire system. This approach removes the guesswork and guarantees performance where loose slats often fall short.

WHAT ARE SUPASLAT PANELS MADE FROM?

IS SUPASLAT A FIRE-RATED TIMBER-STYLE SLAT PANEL?

Vtec’s SupaSlat range is an FR-resistant premium slat panel. It is tested as fully-assembled panels and is classified as B-s2,d0.

This means you can select from over 1900 standard options alone, confident that your selection meets Euroclass B!

Please contact us for classification reports.

IS SUPASLAT AVAILABLE AS FSC® CERTIFIED?

Yes. We are FSC® certified (FSC C160047).

SupaSlat can be produced as FSC Certified. Please talk to us about your specific requirements before quotation.

The Forest Stewardship Council® (FSC®) is a global, not-for-profit organisation dedicated to the promotion of responsible forest management worldwide. FSC defines standards based on agreed principles for responsible forest stewardship that are supported by environmental, social, and economic stakeholders. To learn more, visit www.fsc.org.

What kind of acoustic performance does SupaSlat offer?

Our Supaslat systems are designed not just for aesthetics but also for outstanding acoustic performance. Whether you’re working on a commercial, educational, or hospitality project, our solutions help improve sound quality.

Supaslat is engineered for high-performance sound absorption and diffusion, ideal for reducing echo in large spaces.

Do SupaSlat panels include acoustic backing?

Yes! They include integrated EchoTone acoustic backing board which is available in a variety of standard colours.

Where can I find acoustic data for SupaSlat?

If you are an architect or an acoustic consultant needing acoustic performance data for our Supaslat, simply send us an email, or call us and we’ll get the SupaSlat Acoustic Data Sheet straight to your inbox.

Can SupaSlat be made to fit specific dimensions?

Yes! SupaSlat panels are custom manufactured to your project’s size and layout, avoiding the need for on-site cutting.

DO SUPASLAT PANELS NEED SPECIALIST INSTALLERS?

No, you are restricted to a limited pool of installers. We provide fully detailed instructions to the installer for them to follow.

ARE SUPASLAT PANELS QUICK AND EASY TO INSTALL?

SupaSlat arrives pre-assembled and ready to install, significantly reducing on-site labour time.

We have designed our SupaSlat modules to be simply and rapidly installed – with straightforward methods including Screw Fix or Click Fix.

WHAT ARE THE SUPASLAT INSTALLATION OPTIONS?

Our SupaSlat modules are installed by the below different methods:

Ceiling Installation:

SCREW FIX Panels are screwed with black screws between the slats and through the black backing into the substrate / support work.

CLICK FIX Panels are secret fixed with a Male / Female type engagement system to a variety of substrates / support work systems.

Wall Installation:

SCREW FIX Panels are screwed with black screws between the slats and through the black backing into the substrate / support work.

CLICK FIX Panels are secret fixed with a Male / Female type engagement system to a variety of substrates / support work systems.

HOOK FIX Panels can be secretly fixed with timber split battens, aluminium Z’s or aluminium hockey sticks (supplied by others).

Talk to our Technical Team for assistance with your slatted wall or ceiling application to ensure you get the optimum benefit of the system.

IS THERE ANY ON-SITE CUTTING REQUIRED?

No. Our SupaSlat systems are supplied fully finished to avoid on-site cutting and finishing. They will be delivered ready to fit, with full installation instructions.

CAN SUPASLAT PANELS BE USED IN WETROOMS?

We do not advise direct exposure to water, but they can be used as decorative features in changing areas, spa rooms etc with some precautions.

CAN SUPASLAT PANELS BE USED AS SUSPENDED RAFTS?

Yes, they can. Please discuss these applications with our Technical Department for advice.

DO SUPASLAT PANELS REQUIRE ANY MAINTENANCE?

They are virtually maintenance-free but can benefit from dusting or vacuuming with a soft brush attachment if you wish.

HOW DO YOU CLEAN SUPASLAT PANELS?

Any dirt deposits can be wiped off. However, slats should not be subjected to moisture, wet cloths or any type of detergent or abrasive cleaner.

CAN SUPASLAT PANELS BE RE-USED?

Generally yes. If this is a definite requirement please speak to our Technical Department.

ARE THE COLOURS OF SUPASLAT PANELS SHOWN ONLINE ACCURATE?

The finishes we provide may vary slightly between items and batches. Please note that the colours shown are representative only due to screen resolution issues.

ARE THERE ANY SPECIAL SAFETY PRECAUTIONS TO OBSERVE WITH SUPASLAT PANELS?

Always wear correct PPE when handling, cutting, drilling or working with building materials.

Always fasten each panel safely ensuring it is fully secured.

Read the installation instructions carefully and follow them.

HOW SHOULD SUPASLAT PANELS BE HANDLED & STORED?

Always store the panels in a dry environment

Never lean up against the wall; always ensure they are stored flat with consistent support throughout the panel

Always carry vertically on their edges, never flat

Always protect decorative faces during storage or handling

Observe safe working practices and manual handling procedures

WHY CHOOSE MICROSLAT?

MicroSlat is a Euroclass B classified, affordable fire-rated slatted wood-style panel solution designed for easy installation, and can be cut on-site to suit your requirements.

It is a modular slatted system for walls and ceilings that is easy and quick to install. As well as looking great, there are a range of beautiful finishes to choose from and acoustic benefits.

MicroSlat panels are designed to be simple to handle and easy to cut to shape and size on-site. Standard panel size of 3000 x 600 (mm) means increased coverage and fewer joints – excellent results for projects that want the feel of quality and visual appeal of real wood but without the cost.

WHAT IS MICROSLAT?

The MicroSlat system comprises fr-rated and compliant wood-style slats in a modular panel system for walls and ceilings. Slats are made from our VFR Grey Core material and are finished with our premium Supalami laminate finish to the face of the slat.

WHAT ARE THE SLAT SIZES AND SPACINGS?

Choose from 11 FR standard designs and a range of finishes. Slat widths are 30, 50 or 70mm with spacings ranging from 10-100mm. MicroSlat Product Names show the slat width first, followed by the spacing (mm), as below:

Please view the Technical Data Sheet and Specification Guide for full details.

WHAT ARE THE PANEL DIMENSIONS?

Standard panel sizes are as below (mm):

The extra tall panels can often achieve floor-to-ceiling coverage in a single panel which eliminates horizontal joints for quick installation.

WHAT IS THE PANEL THICKNESS?

HOW HEAVY ARE MICROSLAT PANELS?

MicroSlat panels are designed to be simple to handle and easy to cut to shape and size on-site.

Please view the Technical Data Sheet for full details.

WHAT ARE THE SLAT FINISH OPTIONS?

Vtec’s comprehensive finishing solutions provide you with a fantastic spectrum of cost-effective finishes. Our factory-applied finishes give so much more than “just another covering” and leave you with hundreds of options to choose from to create something truly different for your clients.

WHAT IS THE SLAT CORE COLOUR?

The standard core colour is grey. The exposed slat edges show the VFR Grey Core colour.

IS MICROSLAT A FIRE-RATED TIMBER-STYLE SLAT PANEL?

Yes. MicroSlat is available in FR Grade (Euroclass B Rated) Materials. Please get in touch with us for test data.

Vtec’s MicroSlat FR-rated slats are range-tested as fully assembled panels and are classified as B-s1,d0. This means you can select from over 2000 standard options alone, confident that your selection meets Euroclass B!

Please contact us for classification reports.

Why is MicroSlat supplied as a panel and not loose components?

MicroSlat is delivered as modular aluminium panels to speed up installation and maintain its Euroclass B fire performance. Unlike traditional slatted systems that rely on manual assembly, MicroSlat panels are pre-configured for fast, efficient fitting. They’re also tested with exposed edges, so you can cut them on-site without compromising fire safety. This makes MicroSlat ideal for fast-paced commercial fit-outs where compliance, consistency, and clean visuals are non-negotiable.

Can MicroSlat be cut on-site without affecting its fire rating?

Yes! MicroSlat is tested with exposed edges and maintains its Euroclass B compliance even when site-cut.

CAN MICROSLAT INTEGRATE M&E ACCESS?

Yes. The MicroSlat system integrates easily with access and service requirements, such as:

Please speak to our Technical team if removable panels are required for access behind.

Do I need to assemble MicroSlat panels on-site?

No full assembly is required – MicroSlat is modular and ready to cut and fit to size, streamlining the process.

HOW DO YOU INSTALL MICROSLAT ON WALLS?

MicroSlat Screw Fix system enables simple fastening directly to:

WALLS (Using colour-matched fasteners or discreet brad nails – N.B. Only for Ceilings).

› Solid walls or stud partitions

› Aluminium rails and frames

› Construction boards e.g. ply or mdf – If covered by fire-retardant plasterboard.

HOW DO YOU INSTALL MICROSLAT ON CEILINGS?

MicroSlat Screw Fix system enables simple fastening directly to:

CEILINGS

› Plasterboard (picking up locations to achieve adequate support)

› Aluminium rails

› Unistrut

› Casoline MF

For further details please refer to our Specification Guide or talk to our Product Specialists.

What kind of acoustic performance does MicroSlat offer?

Our MicroSlat systems are designed not just for aesthetics but also for outstanding acoustic performance. Whether you’re working on a commercial, educational, or hospitality project, our solutions help improve sound quality.

MicroSlat panels are backed with our EchoTone Acoustic Backing Board (nominal 9mm thick in Budapest Black, 12mm thick in all other colours) to help absorb unwanted reverberation. Acoustic Absorption varies according to absorbing material, slat sizes, slat spacings, void depth and if further insulation is used.

For improved acoustic performance, create an air gap behind the panel, and for further improvement add Rockwool insulation.

MicroSlat is engineered for high-performance sound absorption and diffusion, ideal for reducing echo in medium and large spaces.

Will I get consistent acoustic performance with MicroSlat?

Yes! MicroSlat’s panel structure ensures consistent performance and avoids errors that can happen with individual slat installs.

WHAT COLOUR IS THE ACOUSTIC BACKING?

MicroSlat is available in a wide range of EchoTone acoustic backing board finishes. Standard acoustic backing is Budapest Black or a range of 25 other colours. Download the Specification Guide for colour choices.

ARE MICROSLAT PANELS EASY TO INSTALL?

MicroSlat modules are designed to be simply and quickly installed to all types of common construction.

It is supplied as modular panels, fully finished, which are then discreetly installed. Panels are easy to cut on-site if needed and they can be fastened to almost any type of common substrate.

ARE MICROSLAT PANELS AVAILABLE AS FSC® CERTIFIED?

The MicroSlat System is FSC® Certified (FSC® C160047).

DO MICROSLAT PANELS REQUIRE ANY MAINTENANCE?

They are virtually maintenance-free but can benefit from dusting or vacuuming with a soft brush attachment if you wish. Do not clean the panels with a damp cloth.

ARE THERE ANY SPECIAL SAFETY PRECAUTIONS TO OBSERVE WITH MICROSLAT PANELS?

Always wear correct PPE when handling, cutting, drilling or working with building materials.

Always fasten each panel safely, ensuring it is fully secured.

Read the installation instructions carefully and follow them.

HOW SHOULD MICROSLAT PANELS BE HANDLED & STORED?

Always store the panels in a dry environment.

Never lean up against the wall; always ensure they are stored flat with consistent support throughout the panel.

Always carry vertically on their edges, never flat.

Always protect decorative faces during storage or handling.

Observe safe working practices and manual handling procedures.

WHY CHOOSE THE MAXIBEAM SYSTEM?

MaxiBeam is a lightweight beam system that provides visual style while also being easy to specify and fast to install.

MaxiBeam is suitable for internal use in many types of environments and sectors:

MaxiBeam can be used on walls, ceilings, suspended rafts or as independent free-standing screens. For details, please download our MaxiBeam Specification Guide.

HOW CAN I SPECIFY MAXIBEAM?

Our MaxiBeam Specification Guide has been designed to introduce you to the MaxiBeam system and take you through the 8 simple steps to specifying MaxiBeam for walls, ceilings, rafts or screens.

Our proven system provides flexible wall and ceiling options to suit your project and deliver strong visual impact alongside unrivalled acoustic performance. MaxiBeam can be adapted easily for different applications and integration requirements, as shown in this guide.

WHAT ARE THE SIZES OF THE BEAMS?

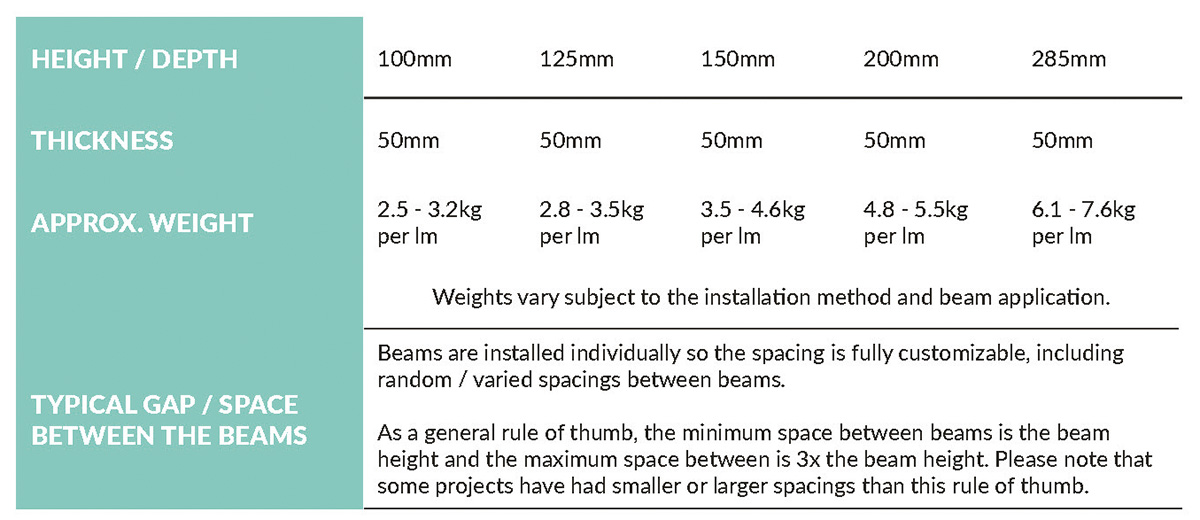

Our standard sizes and weights are:

Bespoke heights and angles are possible with our MaxiBeam system, providing unparalleled creative scope!

For details, please download our MaxiBeam Specification Guide.

HOW HEAVY ARE MAXIBEAMS?

MaxiBeam is lighter than solid oak beams, providing the elegance of heavy-duty timber beams without the hassle of working with solid timber. Each beam is light enough to be carried by a single person.

WHAT THICKNESS ARE MAXIBEAMS?

The normal thickness is 50mm.

WHAT ARE MAXIBEAMS MADE FROM?

CAN MAXIBEAMS BE USED TO CREATE GEOMETRIC SHAPES?

Yes, our MaxiBeam system works amazingly well to create different angles and we’ve collaborated on some exciting bespoke projects. Please get in touch to discuss your application ideas!

CAN MAXIBEAMS BE USED AS SUSPENDED RAFTS?

Yes, our MaxiBeam can be used on walls, ceilings, suspended rafts or as independent free-standing screens. We have worked on a wide variety of projects with different applications. Please discuss your requirements with our Technical Department for advice.

DOES MAXIBEAM INTEGRATE WITH ACCESS & SERVICES WELL?

Yes, MaxiBeam is very flexible and we can work with you to incorporate specific access and service requirements to the best effect. Our team are experienced in overcoming integration challenges and has strong expertise in delivering:

Please talk to our Technical Team about your options.

What kind of acoustic performance does MaxiBeam offer?

Our Maxibeam system is designed not just for aesthetics but can also provide outstanding acoustic performance. Whether you’re working on a commercial, educational, or hospitality project, our solutions help manage reverberation and improve sound quality and clarity.

Maxibeam is both aesthetic and functional, designed to incorporate complementary acoustic treatment perfectly while maintaining a lightweight structure.

ARE MAXIBEAMS FIRE RESISTANT?

MaxiBeam is a fully constructed unit that has been range-tested for fire classification Euroclass B-s2,d0 as an assembled unit.

Contact us for our test data report.

Does MaxiBeam meet international standards for low VOC emissions?

Yes, MaxiBeam meets and exceeds several rigorous international standards for low Volatile Organic Compound (VOC) emissions:

These certifications ensure that MaxiBeam is safe for indoor environments, contributes to healthier buildings, and supports green building certifications like BREEAM and WELL.

IS MAXIBEAM AVAILABLE AS FSC® CERTIFIED?

Yes. We are FSC® Certified (FSC® C160047) .

MaxiBeam can be produced as FSC® Certified. Please talk to us about your specific requirements before the quotation.

The Forest Stewardship Council® (FSC®) is a global, not-for-profit organisation dedicated to the promotion of responsible forest management worldwide. FSC defines standards based on agreed principles for responsible forest stewardship that are supported by environmental, social, and economic stakeholders. To learn more, visit www.fsc.org.

DO MAXIBEAMS NEED SPECIALIST INSTALLERS?

No, we are not restrictive and provide detailed instructions to the installer for them to follow.

ARE MAXIBEAMS QUICK TO INSTALL?

Our MaxiBeam system is designed for quick installation – with either a fixing cleat, screw from the rear or click-fix. Please talk to our Technical Team about your options.

HOW IS MAXIBEAM INSTALLED?

MaxiBeam is supplied as individual beams, which are discreetly installed on ceilings & walls or installed as suspended rafts & free-standing screens. Beams can be installed so they are removable if required – please contact our Technical Department if this is a requirement.

IS THERE ANY ON-SITE CUTTING REQUIRED?

No on-site cutting should be required. MaxiBeam systems are supplied fully finished to avoid on-site cutting and finishing. If beams do require cutting, this can be carried out with standard woodworking tools.

CAN MAXIBEAMS BE USED IN WETROOMS?

We do not advise direct exposure to water, but they can be used as decorative features in changing areas, spa rooms etc with some precautions. Please contact our Technical Department if this is a requirement.

DO MAXIBEAMS REQUIRE ANY MAINTENANCE?

They are virtually maintenance-free but can benefit from dusting or vacuuming with a soft brush attachment if you wish.

HOW DO YOU CLEAN MAXIBEAMS?

Any dirt deposits can be wiped off. However, beams should not be subjected to moisture, wet cloths or any type of detergent or abrasive cleaner.

CAN MAXIBEAMS BE RE-USED?

Generally yes. If this is a definite requirement please speak to our Technical Department.

ARE THE COLOURS OF MAXIBEAM SHOWN ACCURATE?

The finishes we provide may vary slightly between items and batches. Please note that the colours shown are representative only due to screen resolution issues.

ARE THERE ANY SPECIAL PRECAUTIONS TO OBSERVE WITH MAXIBEAM?

Always wear correct PPE when handling, cutting, drilling or working with building materials.

Always fasten each panel safely.

HOW SHOULD MAXIBEAM BE HANDLED & STORED?

Always store the MaxiBeams in a dry environment.

Never lean up against the wall; always ensure they are stored flat with consistent support throughout the MaxiBeams.

Always carry vertically on their edges, never flat.

Always protect decorative faces during storage or handling.

Observe safe working practices and manual handling procedures.

Are Supaslat and Microslat panels fully fire-rated as complete systems?

Yes. Both Supaslat and Microslat are tested and classified as full panel assemblies to Euroclass B fire performance standards.

Unlike individual timber slats installed separately on-site, these systems ensure complete compliance with fire regulations—reducing the risk of non-compliance and rework.

How do Supaslat and Microslat panel systems save time on-site?

Supaslat and Microslat are supplied as pre-assembled, modular panels, significantly reducing installation time compared to individual slats.

Microslat panels are ready to cut without compromising their fire performance, and Supaslat panels are custom-manufactured to your project dimensions—no cutting, no mess, and fewer labour hours.

Download our helpful guide on The 12 Key Reasons why Panelised Systems Win.

Why are SupaSlat and MicroSlat supplied as panel systems instead of loose components?

Both SupaSlat and MicroSlat are supplied as pre-assembled panel systems to deliver superior performance, faster installation, and full fire compliance. Unlike traditional slatted solutions using individual strips, these systems are manufactured off-site to exact specifications, ensuring consistency in appearance, acoustic function, and Euroclass B fire rating.

SupaSlat panels are made to measure, eliminating the need for on-site cutting. MicroSlat panels are precision-engineered and are delivered ready to cut to fit and are tested to retain their fire performance even with exposed edges. This modular approach removes the risks, delays, and inconsistencies associated with assembling loose slats on-site.

What makes Supaslat and Microslat better than slat systems built on-site?

Unlike slatted designs built manually on-site, Supaslat and Microslat offer consistent quality, hidden fixings, pre-integrated acoustics, and coordinated service layouts. This eliminates the risk of errors, poor visual alignment, or compliance failures, and speeds up your project delivery.

Can Supaslat and Microslat panels be integrated with lighting, HVAC or access points?

Yes. Supaslat is fully modelled in 3D before manufacture, allowing for precise service integration and access panel planning. Microslat can also accommodate service cutouts where needed. This ensures seamless coordination with M&E systems from the outset—no surprises on-site.

Are the acoustic backings in Supaslat and Microslat optional or built-in?

The acoustic performance is integrated into the panel system. Supaslat uses EchoTone acoustic backing with up to 26 standard colour options. Microslat also includes EchoTone. This built-in approach ensures consistent, reliable performance, unlike loose acoustic components that can be forgotten or mis-installed on-site.

How do SupaSlat and MicroSlat help keep projects on budget?

Both systems are value-engineered to suit a wide range of budgets without compromising on design intent. The modular nature, reduced on-site labour, and minimal waste all contribute to lower overall installed cost compared to traditional slatted systems.

What finish options are available with SupaSlat and MicroSlat?

Supaslat is available in a wide selection of Supalami laminates, to suit commercial architectural interiors. Microslat offers Supalami timber-style laminate slats that are durable, lightweight, and suited for high-traffic environments. Both can be specified to match design and performance requirements.

Are drawings and technical documentation provided with SupaSlat and MicroSlat?

Yes. Each system is delivered with comprehensive installation drawings, panel layouts, and fixing details. This reduces coordination time on-site and makes repeat specification on future phases or projects straightforward and reliable.

How do SupaSlat panels save installation time?

Each SupaSlat panel is supplied pre-fabricated and project-specific, eliminating the need for on-site cutting or adjustments. The modular design means you cover more area per panel, drastically reducing installation hours.

Can MicroSlat panels be cut on-site without affecting fire rating?

Yes, MicroSlat panels can be cut on-site without compromising fire safety. They’ve been fully range-tested with exposed edges, ideal for fast-paced installs.